For some of us, this is an exciting phase. Not because it’s actually interesting or there’s much to look at, but because it signals the start of the construction project! After months of paperwork, the dream starts to feel alive now.

Your site supervisor will usually inform you when the slab will be laid. If you would like to perform a ground breaking ceremony, the best time to do so is prior to the slab being laid.

This stage is a process that may take a few days. Initially, temporary fencing will be erected around the site, usually about 1.8 m high but doesn’t actually stop anyone from getting in if they tried. It’s usually to satisfy OH&S regulations, so that you can’t accidentally walk onto a worksite and hurt yourself.

Power supply will then be installed. Usually, this is a box standing on a pole until it’s properly secured and attached to the house.

A portable toilet will be plonked at the front of the site, along with a wire mesh bin for construction rubbish. Again the toilet is for OH&S purposes. I have honestly not ever seen any tradie use one as these are pretty disgusting. Tradies probably head out to MacDonald’s or a shopping centre to use the toilets when they drive out to grab a bite.

Next up, the site gets cleared of topsoil, vegetation and any rubbish. The site is also pegged out in preparation for excavation works. Plumbers the come onto the site to connect sewer, waste and water pipes.

Word of caution: If you notice any pipes that might be located in the wrong spot, now is the time to raise the alarm. Once the slab is laid, it is next to impossible to get the builder to agree to rectify any errors.

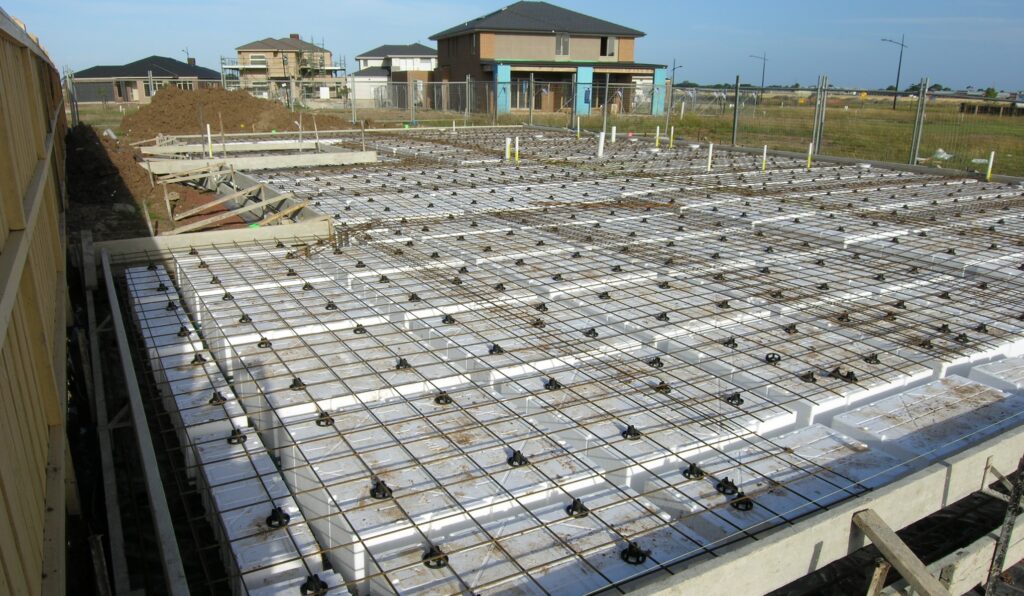

The next stage involves the concreters who will build the timber outline for the slab, fill the base with sand/gravel, then put in the waffle pods and waterproofing membrane.

Finally, concrete is poured and the slab is left to ‘cure’. It is said that the concrete takes at least 30 days to ‘cure’. However, you will find that most builders will commence building almost immediately.

The slab stage is quite a fast process if there isn’t inclement weather. If it’s too windy, the polystyrene may be blow away while being pinned into place with steel frames and clips. If it’s raining heavily, the slab cannot be poured. Your builder usually allows for a few days of delays due to inclement weather in the contract. Take note of this prior to signing the contract.

Waffle Slabs

Victoria currently builds slabs known as ‘waffle slab’. This is a space saving technique where polystyrene is used within concrete slabs in order to limit the amount of concrete required to build a concrete slab. Once the polystyrene and steel are covered with concrete, all you see is the finished concrete which looks the pretty much the same as the traditional raft slab.

Across Victoria, particularly in housing estates built over the last twenty years, waffle slabs are common in homes built by volume builders. Waffle slabs conform to the AS 2870, which is the Australian Standard for Residential Slabs and Footings. However, care needs to be taken in using them particularly on highly reactive clay sites, sloping sites, fill sites, or locations where drainage is a problem.

Waffle pod slabs have been linked to a phenomenon known as slab heave, where the slab lifts causing cracking and damage to the building frame. Windows and doors get stuck or won’t open or shut. Some volume builders usually advise you to construct a concrete path around the around to prevent slab heave. The concreter will usually build this concrete path with a slight slant (or ‘flow) so that water flows away from the house, reducing moisture build up around the slab.

Useful Links

Waffle Pod Slabs Vs Raft Slabs

Waffle slab warning for residents of Melbourne’s western suburbs

Your Home, a Government website